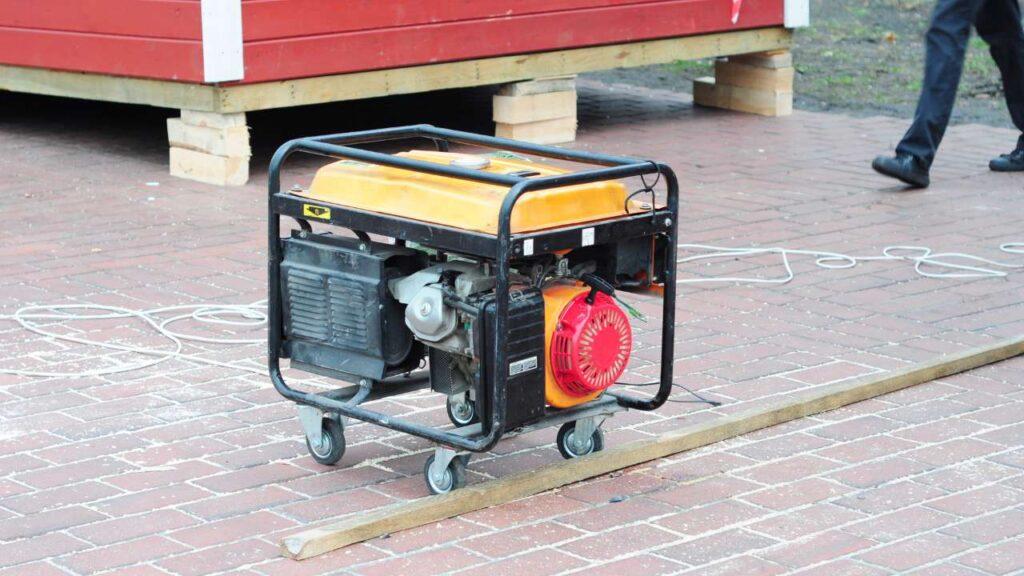

Have you ever needed to switch between different fuels in your dual fuel generator? This versatile tool lets you choose between gasoline, propane, or other types of fuel, depending on what’s available or cheaper at the time. In this article titled “How to Switch Between Fuels in Dual Fuel Generators,” we’ll walk you through the essential steps to make this switch smoothly and safely. By the end of this guide, you’ll know exactly how to manage your generator’s fuel sources effectively. Let’s dive in and learn how to optimize your generator’s performance with different fuels!

Key Components Involved in Fuel Switching

Switching fuels in a dual fuel generator isn’t just a matter of choosing one fuel over the other; it involves understanding and managing several critical components. These components ensure that the switch can be made safely and efficiently, optimizing the generator’s performance across different fuel types. Let’s examine these components closely to better understand their roles and maintenance requirements and how this feature helps generators for emergency home backup.

Fuel Selector Switch

Before diving into the mechanics, it’s essential to grasp the pivotal role of the fuel selector switch in dual fuel generators. This switch is not merely a control feature; it’s the gateway between different fuel sources, enabling a seamless transition based on your needs.

- Functionality: Central to switching operations, this switch allows you to choose the desired fuel source effortlessly. It’s typically designed for user-friendly operation, ensuring quick adjustments even in emergency situations.

- Maintenance Tips: Regular maintenance is crucial. Check for any signs of mechanical failure or wear that could affect performance. Lubricating the switch and ensuring it’s clean from debris can prevent operational issues.

The fuel selector switch is a fundamental component that ensures your dual fuel generator can adapt to varying fuel availability, making it a versatile choice for various applications. Ensuring its proper function and maintenance is key to reliable generator operation.

Carburetor Adjustment

The carburetor plays a crucial role when changing fuels, as each type of fuel requires different air-to-fuel ratios for efficient combustion. Understanding and adjusting your generator’s carburetor is vital for maintaining performance when switching fuels.

- Purpose of Adjustments: Adjusting the carburetor helps accommodate the varying combustion characteristics of different fuels, ensuring the engine operates efficiently without risking damage.

- How to Adjust: This usually involves fine-tuning the air-fuel mixture screw to achieve optimal performance. Always refer to the manufacturer’s manual for specific guidance, or consult with a professional to avoid mishandling.

Regular carburetor adjustment is essential, especially when switching fuels frequently. This ensures that your generator runs smoothly, regardless of the fuel type being used, and maintains its efficiency and lifespan.

Fuel Lines and Filters

Fuel lines and filters are the circulatory system of any generator, ensuring that fuel reaches the engine cleanly and without obstruction. Proper maintenance of these components is critical, especially when switching between different types of fuels, which may have varying chemical compositions.

- Role of Fuel Lines and Filters: They transport fuel from the tank to the engine and ensure that it is free of impurities that could clog the engine’s inner workings or degrade its performance.

- Inspection and Replacement: Regular inspections for leaks, cracks, or wear are essential. Ensure that the filters are capable of handling the type of fuel used and replace them according to the manufacturer’s recommendations or if any damage is observed.

Maintaining the integrity of your fuel lines and filters is crucial for the safe and efficient operation of your dual fuel generator. Ensuring that these components are in good condition not only enhances performance but also extends the lifespan of your generator.

These key components are essential for the smooth and efficient operation of dual fuel generators. By understanding their functions and maintaining them properly, you can ensure that your generator remains reliable, no matter the fuel type you choose to use. This attention to detail will provide peace of mind and operational efficiency, making your investment in a dual fuel generator all the more worthwhile.

Preparing to Switch Fuels

Switching fuels in a dual fuel generator involves more than just flipping a switch. Proper preparation is crucial to ensure the switch is safe and the generator operates efficiently on the new fuel. This section will guide you through the necessary steps to prepare your generator for a smooth and safe transition between fuel types.

Safety First

Before making any changes, it’s paramount to prioritize safety to prevent accidents and damage to your generator.

- Turn Off the Generator: Always ensure the generator is off and cool to the touch before starting any work on it. This prevents accidental ignition or burns.

- Work in a Well-Ventilated Area: Generators emit fumes that can be hazardous. Always work outdoors or in a well-ventilated space to avoid inhalation of toxic gases.

- Wear Protective Gear: Use gloves and safety glasses to protect yourself from spills and splashes when handling fuel.

Ensuring these safety measures are in place is the first step towards a successful fuel switch. These precautions protect both you and the generator, setting the stage for a secure maintenance process.

Checking Manufacturer Guidelines

Understanding the specific needs of your generator model is key to a successful fuel switch.

- Consult the Owner’s Manual: The manual contains specific instructions on how to handle fuel changes for your particular model, which can vary significantly between different generators.

- Check for Specific Tools Required: Some fuel switches may require special tools or attachments. These will be listed in your generator’s manual.

Adhering to the manufacturer’s guidelines not only ensures safety but also helps maintain the warranty and optimal functioning of your generator. This step is about understanding the unique needs of your equipment and preparing accordingly.

Necessary Tools and Supplies

Having the right tools and supplies on hand is crucial for a smooth and efficient switch.

- Gather Essential Tools: Typically, you might need wrenches, screwdrivers, and possibly a funnel for adding new fuel.

- Fuel Canisters: Have appropriate containers for both types of fuel, ensuring they are clean and free from contaminants.

- Fuel Stabilizer: This is especially important if one type of fuel will remain in the generator for an extended period.

Collecting these items before you start the fuel switch can streamline the process and minimize the risk of interruptions. Being well-prepared with the right tools and supplies sets the foundation for a successful transition to a different fuel type.

Taking these preparatory steps seriously ensures your safety and the smooth operation of your dual fuel generator during the fuel switch. With everything in place, you can proceed confidently, knowing that you’re ready for a secure and efficient transition.

Step-by-Step Guide to Switching Fuels

Now that you’re prepared with the right tools, safety measures, and know-how, it’s time to actually switch the fuels in your dual fuel generator. This process, when done correctly, can significantly extend the life and efficiency of your generator. Let’s walk through each step to ensure you can confidently and safely make the switch from one fuel type to another.

Step 1: Fuel Drainage

Before introducing a new type of fuel to your generator, it’s important to properly drain any existing fuel to prevent mixing, which could affect performance or cause damage.

- Ensure Complete Drainage: Make sure all the fuel is drained from the tank to avoid contamination. This might involve running the generator until it uses up the fuel currently in the system.

- Safe Disposal of Old Fuel: Dispose of the old fuel properly according to local environmental regulations to avoid any harmful impacts.

Draining the old fuel completely is a critical step in preparing your generator for a smooth transition to a new fuel type, ensuring that performance remains optimal.

Step 2: Setting the Fuel Selector

The fuel selector switch is your tool for choosing which fuel to use. It’s crucial that this switch is set correctly to ensure the generator operates on the desired fuel type.

- Switching Process: Locate the fuel selector switch and turn it to the position of the new fuel type you wish to use.

- Confirm Position: Double-check that the switch is firmly set to prevent any accidental switching or fuel mix-ups.

Setting the fuel selector properly guarantees that your generator will draw from the correct fuel source, thus optimizing its efficiency and effectiveness.

Step 3: Fuel Line and Filter Checks

Ensuring that the fuel lines and filters are in good condition and properly configured for the new fuel type is essential for maintaining the health of your generator.

- Inspect and Replace if Necessary: Check the fuel lines and filters for any signs of wear or damage. Replace them if they are not rated for both types of fuel or if they show any signs of deterioration.

- Ensure Proper Connections: Secure all connections to avoid leaks, which could lead to inefficiency or safety hazards.

Regular inspection and maintenance of fuel lines and filters are crucial to prevent issues that could impair your generator’s performance.

Step 4: Priming the Generator

Once the new fuel is in place and everything is set, priming the generator ensures that the fuel system is ready to deliver the new fuel efficiently.

- Follow Manufacturer Instructions: Use the primer button if available, or follow specific manual instructions to prime the generator.

- Check for Smooth Operation: Ensure that the fuel flow is steady and that there are no signs of blockage or leakage.

Priming your generator helps in ensuring that the new fuel is properly introduced into the system, readying it for efficient operation.

Step 5: Starting the Generator

With everything checked and set, it’s time to start your generator and begin using the new fuel.

- Start According to Manual: Turn the generator on following the manufacturer’s starting procedure to avoid any operational issues.

- Monitor Performance: Initially, keep an eye on the generator’s performance to ensure that it runs smoothly on the new fuel without any issues.

Starting your generator properly after a fuel switch is crucial to verify that all systems are operating as they should, with the new fuel type providing optimal performance.

By following these detailed steps, you can confidently switch fuels in your dual fuel generator, ensuring safety, efficiency, and prolonged life for your equipment.

Tips for Efficient Fuel Management

Effectively managing the types of fuel you use in your dual fuel generator not only enhances its performance but also maximizes its lifespan. This section provides you with practical tips to ensure you are using your fuel resources wisely and maintaining your generator in top condition.

Balancing Fuel Types

Understanding how to balance the use of different fuels can lead to better efficiency and cost-effectiveness. Here’s how you can manage this balance:

- Rotate Fuels Regularly: Alternating between fuels not only ensures that both fuel systems remain in good working order but also helps in utilizing fuels based on their availability and price fluctuations.

- Monitor Fuel Efficiency: Pay attention to how your generator performs with each type of fuel. Some fuels may burn more efficiently and provide more power than others.

Balancing fuel types not only optimizes the use of available resources but also prepares you for situations where one type of fuel might be harder to obtain.

Monitoring Performance

Keeping an eye on how your generator performs with different fuels can alert you to potential issues before they become serious.

- Track Fuel Consumption: Note how quickly your generator uses each type of fuel. Unexpected increases in fuel consumption can indicate issues such as leaks or inefficiencies.

- Listen for Irregularities: Changes in sound can indicate problems. A smooth, consistent operation usually means everything is working correctly.

ThisrRegular monitoring allows you to maintain your generator at peak efficiency, ensuring it’s always ready when you need it.

Regular Maintenance Tips

Regular maintenance is key to extending the life of your dual fuel generator and ensuring it operates safely and efficiently.

- Regular Inspections: Check your generator before and after each use, looking for any signs of wear or damage that could affect its operation.

- Clean and Replace Filters Regularly: Keeping filters clean prevents clogs and keeps your engine running smoothly. Replace filters according to the manufacturer’s guidelines.

- Schedule Professional Check-ups: Having a professional inspect your generator can help catch issues you might miss and keep your machine running in top condition.

Adopting these maintenance practices will help ensure that your dual fuel generator remains reliable and efficient, ready to serve your needs whether at home, work, or in an emergency situation. By following these tips for efficient fuel management, you not only ensure that your generator remains functional and efficient but also save on maintenance costs and fuel expenses.

Wrapping It Up!

Alright, you’ve learned quite a bit about switching fuels in your dual fuel generator! It’s pretty cool how versatile these generators are, allowing you to pick between different fuels depending on what’s available or cheaper. By understanding the key components, preparing properly, and following the step-by-step guide, you’re all set to manage your generator like a pro. Don’t forget the tips we covered on balancing fuel types and keeping an eye on how your generator performs. Regular maintenance isn’t just a good habit; it’s a must to keep your generator running smoothly and efficiently. If you ever run into hitches, just remember the basics we went through, and you’ll be back on track in no time!

Related FAQs

Can I Mix Gasoline And Propane In My Dual Fuel Generator?

No, you should not mix gasoline and propane in your dual fuel generator as it can damage the engine and reduce performance.

How Often Should I Switch Fuels In My Dual Fuel Generator?

It’s best to switch fuels regularly to keep both systems in good working condition and ensure fuel does not degrade over time.

What Are The Signs Of Inefficient Fuel Use In Dual Fuel Generators?

Signs of inefficient fuel use include increased fuel consumption, reduced power output, and unusual engine noises.

Is It Safe To Switch Fuels While The Generator Is Running?

No, always turn off your generator and ensure it is cool before switching fuels to prevent safety hazards.

Which Fuel Is More Economical For Dual Fuel Generators?

The economy depends on local fuel prices and availability; typically, propane is cheaper and burns cleaner than gasoline.

At our core, we’re a group of passionate generator, inverter, solar energy, battery enthusiasts. We dive deep into the world of tech, especially when it’s about powering your home, RV or outdoors. We try to provide as much value to the readers with our information and how to blog articles as possible. For affiliate articles our honest and transparent reviews of essential tech products are rooted in real-world experience. We take great satisfaction in offering unbiased evaluations, ensuring that you can make informed decisions when investing in your desired techs.